I-Factory Outlets Automated Assembly Line Umshini Wokuhlanganisa Ozenzakalelayo Umshini Wokukhiqiza Okuzenzakalelayo

Ukwanelisa injabulo elindelwe kakhulu yamakhasimende , sineqembu lethu eliqinile lokuhlinzeka ngomhlinzeki wethu omkhulu kunabo bonke ohlanganisa ukukhangisa, imali engenayo, ukuvela, okukhiphayo, ukuphathwa kwekhwalithi, ukupakisha, ukugcinwa kwempahla kanye nempahla ye-Factory Outlets Automated Assembly Line. Umshini Wokuhlanganisa Ozenzakalelayo Wokukhiqiza Ulayini, Ukuphila ngekhwalithi enhle, ukuthuthuka ngamaphuzu esikweletu kuwumsebenzi wethu waphakade, Sinomuzwa onamandla wokuthi ngemva nje kokubuka kwakho sizoba abangane besikhathi eside.

Ukwanelisa injabulo elindelwe kakhulu yamakhasimende , sineqembu lethu eliqinile ukuze sinikeze abahlinzeki bethu abakhulu kunabo bonke abahlanganisa ukukhangisa, imali engenayo, ukuvela, okukhiphayo, ukuphathwa kwekhwalithi, ukupakisha, ukugcinwa kwempahla kanye nempahlaChina Assemble and Terminal, Ukuze kuhlangatshezwane nezidingo zemakethe ezengeziwe kanye nentuthuko yesikhathi eside, ifektri entsha engu-150, 000-square-metres isakhiwa, ezosetshenziswa ngo-2014. Khona-ke, sizobe siphethe umthamo omkhulu wokukhiqiza.Yebo, sizoqhubeka nokuthuthukisa uhlelo lwesevisi ukuze luhlangabezane nezidingo zamakhasimende, ukuletha impilo, injabulo nobuhle kuwo wonke umuntu.

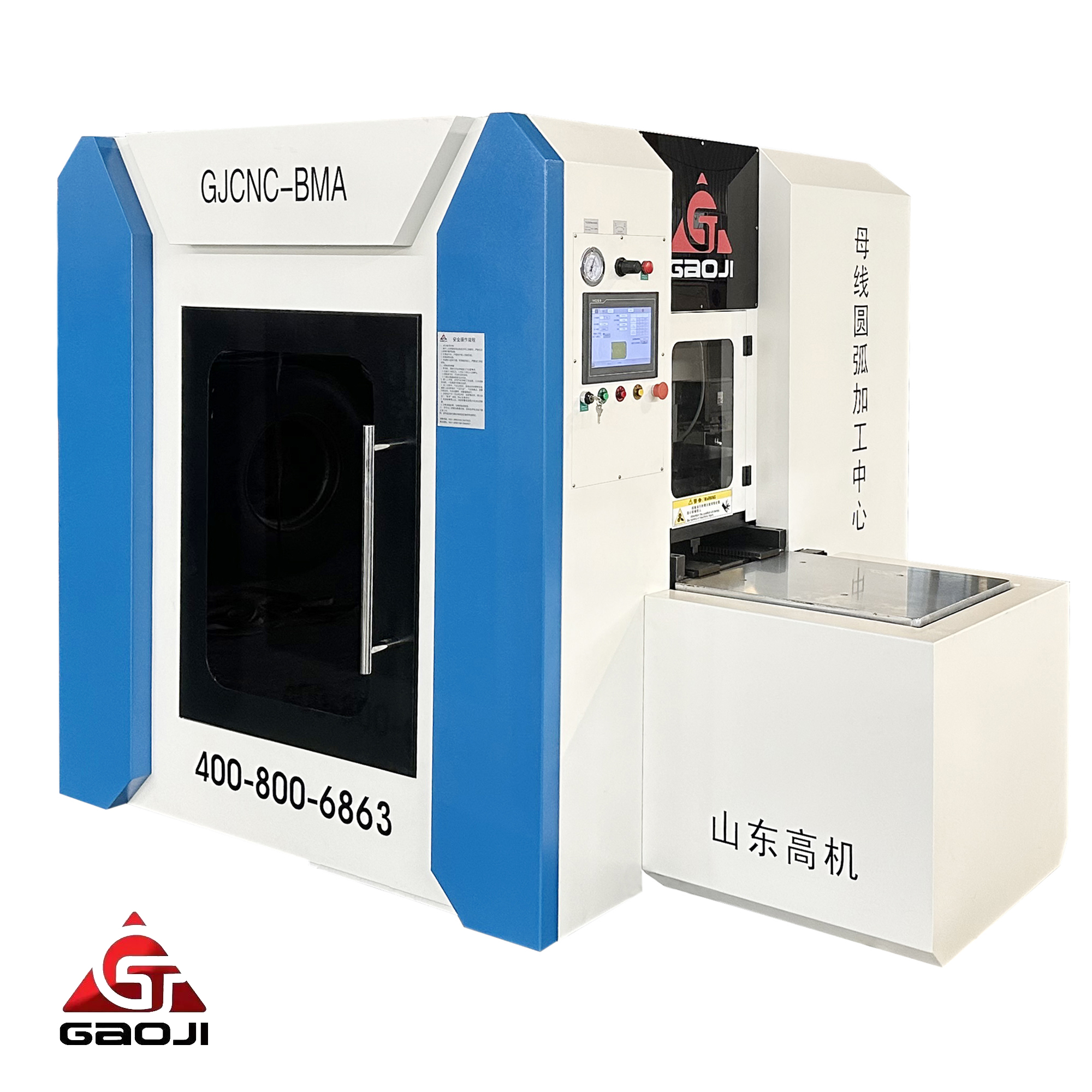

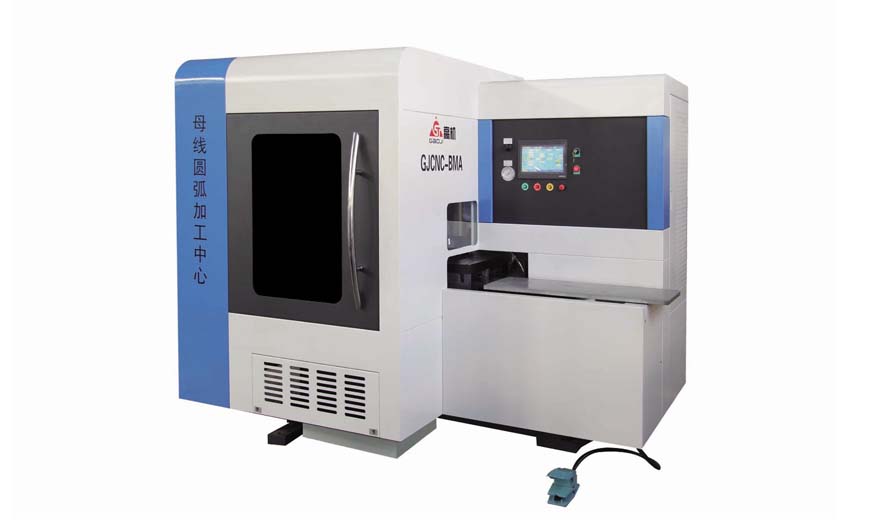

Imininingwane Yomkhiqizo

Umshini wokugaya ibhasi we-CNC usebenza ikakhulukazi ku-milling fillet kanye ne-fillet enkulu kubha yebhasi.Ikhiqiza ngokuzenzakalelayo ikhodi yohlelo futhi idlulisele ikhodi emishinini isekelwe ezidingweni zebha yebhasi kanye nokokufaka kwedatha esikrinini sokubonisa.Kulula ukuyisebenzisa futhi ingasebenza ngomshini i-busbar arc ebukekayo.

Inzuzo

Lo mshini usetshenziselwa ukwenza imishini ye-arc yesigaba yamakhanda ebhasi nge-H≤3-15mm, w≤140mm kanye ne-L≥280mm.

Ikhanda lebha lizokwenziwa ngomshini ukuze libe nesakhiwo esinqunyiwe.

Ama-clamp asebenzisa ubuchwepheshe be-automatic centering ukuze ucindezele ikhanda elicindezelayo kangcono endaweni yokubeka amandla.

I-booster isetshenziswa ekhanda elicindezelayo ukuze kuvikelwe ukuzinza kwe-workpiece, inikeze umphumela ongcono womshini wokusebenza.

Isibambi sethuluzi se-BT40 esisezingeni lomhlaba sisetshenziselwa ukushintshwa kalula kwe-blade, ukuqina okuhle kanye nokunemba okuphezulu.

Lo mshini usebenzisa izikulufu zebhola ezinemba okuphezulu nemihlahlandlela ewumugqa.Kukhethwe ama-rail omhlahlandlela anosayizi omkhulu osindayo ukuze anikeze ukuqina okungcono kwawo wonke umshini, ehlise ukudlidliza nomsindo, athuthukise ikhwalithi yesiqeshana sokusebenza futhi aqinisekise ukunemba okuphezulu nokusebenza kahle.

Usebenzisa izingxenye zemikhiqizo yasekhaya neyaziwayo emhlabeni wonke, lo mshini unomsebenzi omude futhi ungaqinisekisa izinga eliphezulu.

Uhlelo olusetshenziswa kulo mshini isoftware eshumekiwe yezithombe ezishumekiwe ezakhiwe inkampani yethu, ibona ukuzenzela ohlelweni.Umsebenzisi akudingeki ukuthi aqonde amakhodi ahlukahlukene, futhi akudingeki ukuthi azi ukuthi asetshenziswa kanjani isikhungo somshini esivamile.Umsebenzisi kufanele afake amapharamitha ambalwa ngokubhekisela ezithombeni, futhi okokusebenza kuzokhiqiza ngokuzenzakalelayo amakhodi omshini.Kuthatha isikhathi esifushane kunokuhlelwa kwezandla futhi kuqeda amandla ephutha lekhodi elibangelwa ukuhlela okwenziwa ngesandla.

I-Busbar efakwe kulo mshini ibukeka kahle, ngaphandle kokukhipha amaphuzu, inciphisa usayizi wekhabhinethi ukuze konge isikhala futhi kunciphise ngokuphawulekayo ukusetshenziswa kwethusi.

Ukwanelisa injabulo elindelwe kakhulu yamakhasimende , sineqembu lethu eliqinile lokuhlinzeka ngomhlinzeki wethu omkhulu kunabo bonke ohlanganisa ukukhangisa, imali engenayo, ukuvela, okukhiphayo, ukuphathwa kwekhwalithi, ukupakisha, ukugcinwa kwempahla kanye nempahla ye-Factory Outlets Automated Assembly Line. Umshini Wokuhlanganisa Ozenzakalelayo Wokukhiqiza Ulayini, Ukuphila ngekhwalithi enhle, ukuthuthuka ngamaphuzu esikweletu kuwumsebenzi wethu waphakade, Sinomuzwa onamandla wokuthi ngemva nje kokubuka kwakho sizoba abangane besikhathi eside.

Izitolo zasefekthriChina Assemble and Terminal, Ukuze kuhlangatshezwane nezidingo zemakethe ezengeziwe kanye nentuthuko yesikhathi eside, ifektri entsha engu-150, 000-square-metres isakhiwa, ezosetshenziswa ngo-2014. Khona-ke, sizobe siphethe umthamo omkhulu wokukhiqiza.Yebo, sizoqhubeka nokuthuthukisa uhlelo lwesevisi ukuze luhlangabezane nezidingo zamakhasimende, ukuletha impilo, injabulo nobuhle kuwo wonke umuntu.

Ukucushwa

| Ubukhulu (mm) | Isisindo (kg) | Usayizi Wethebula Lokusebenza (mm) | Umthombo womoya (Mpa) | Amandla Aphelele (kw) |

| 2500*2000 | 3300 | 350*900 | 0.5~0.9 | 11.5 |

Imingcele Yezobuchwepheshe

| Amandla kaMoter (kw) | 7.5 | Amandla e-Servo (kw) | 2*1.3 | I-Max Torpue (Nm) | 62 |

| Imodeli Yomphathi Wamathuluzi | I-BT40 | Ububanzi Bethuluzi (mm) | 100 | Isivinini se-Spindle (RPM) | 1000 |

| Ububanzi Bezinto (mm) | 30-140 | Ubude Bezinto Ezincane (mm) | 110 | Ubukhulu Bezinto (mm) | 3~15 |

| I-X-Axis Stoke (mm) | 250 | I-Y-Axis Stoke (mm) | 350 | Isivinini Sokuma Esisheshayo (mm/min) | 1500 |

| I-Pitch of Ballscrew (mm) | 10 | Ukunemba Kwesikhundla (mm) | 0.03 | Isivinini Sokudla (mm/min) | 1200 |