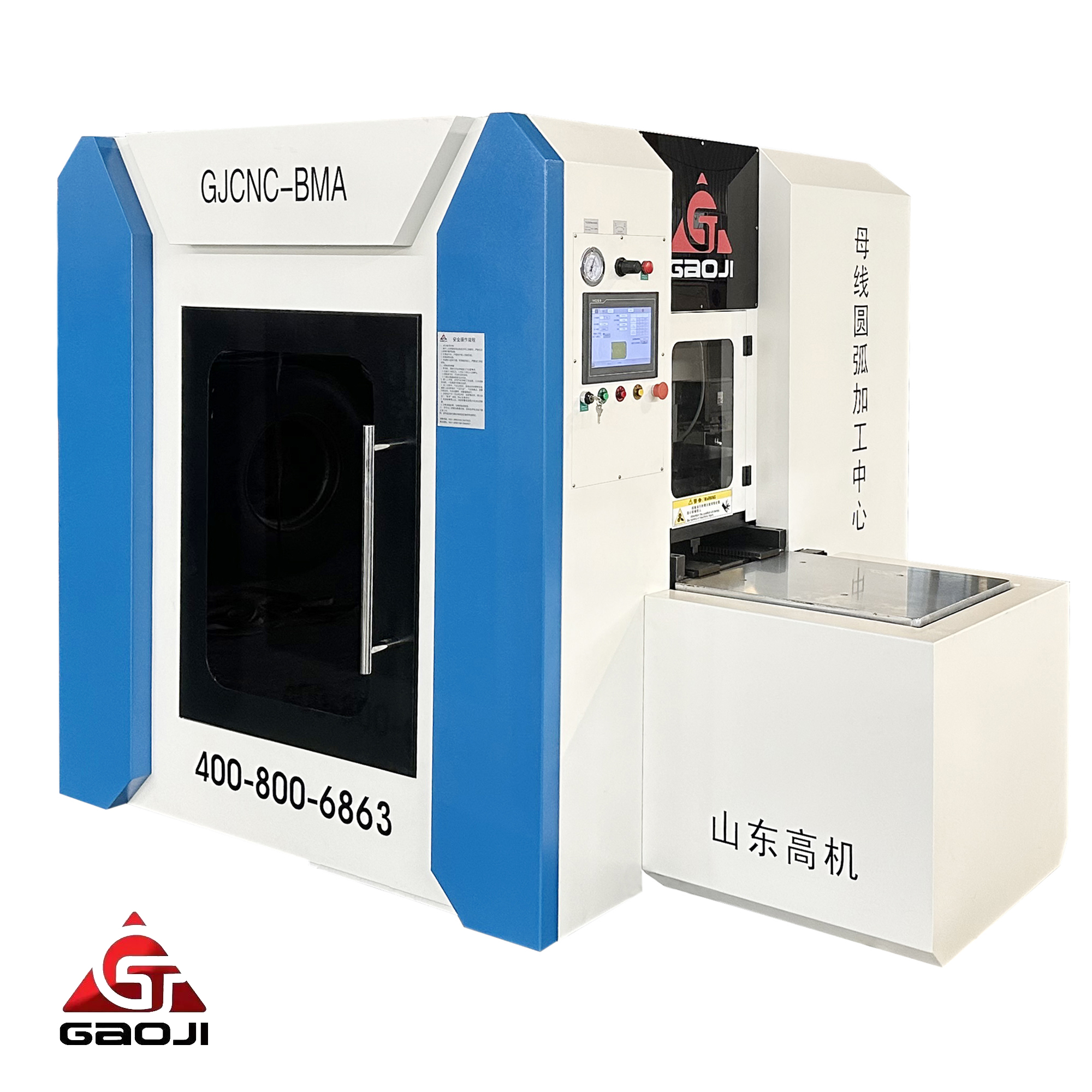

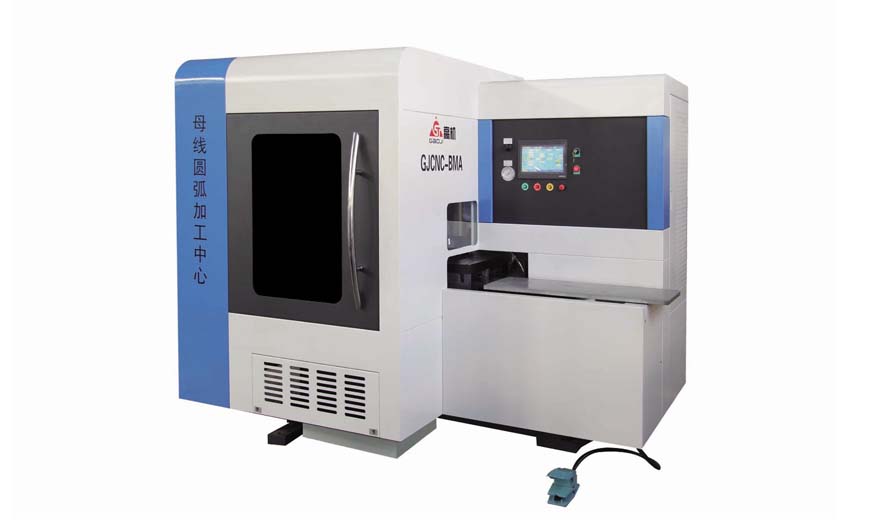

I-MOQ Ephansi ye-CNC Copper High Effiency Automatic Busbar Bending Punching Cutting Processing Machine

Le nkampani isekela ifilosofi ethi “Yiba No.1 ngokuhle kakhulu, gxila esilinganisweni sesikweletu kanye nokwethembeka ukuze ukhule”, izoqhubeka nokusebenzela amakhasimende asebekhulile namasha avela ekhaya nakwamanye amazwe ngokushisa okuphelele kwe-MOQ Ephansi ye-CNC Copper High Effiency Automatic Busbar Bending Punching Cutting Machine, Senza konke okusemandleni ethu ukuhlinzeka ngosizo oluzuzisa kakhulu kubathengi abaningi nosomabhizinisi.

Le nkampani isekela ifilosofi ethi “Yiba yiNombolo 1 ngokuhle kakhulu, gxila ekulinganisweni kwesikweletu kanye nokwethembeka ukuze ukhule”, izoqhubeka nokusebenzela amakhasimende asebekhulile nabasha abavela ekhaya nakwamanye amazwe ngentshiseko enkulu.Umshini Wokusika waseShayina Wemishini Yebhasi Nebhasi YokubhobozaNjengoba umgomo wokusebenza “ugxile emakethe, ukwethembeka njengomgomo, ukuzuza kowina njengomgomo”, sibambelele “kumakhasimende kuqala, isiqinisekiso sekhwalithi, isevisi kuqala” njengenhloso yethu, ezinikele ekuhlinzekeni ikhwalithi yokuqala, ukudala isevisi yobuhle, sithole udumo nokwethenjwa embonini yezingxenye zezimoto. Esikhathini esizayo, sizohlinzeka ngomkhiqizo osezingeni eliphezulu kanye nensizakalo enhle kakhulu njengokubuyisela kumakhasimende ethu, samukele noma yiziphi iziphakamiso kanye nempendulo evela emhlabeni wonke.

Imininingwane Yomkhiqizo

Umshini wokugaya i-busbar we-CNC usebenza kakhulu ku-milling fillet kanye ne-big fillet ku-busbar. Ukhiqiza ngokuzenzakalelayo ikhodi yohlelo futhi udlulisele ikhodi emishinini ngokusekelwe ezidingweni ezichazwe ku-busbar kanye nokufakwa kwedatha esikrinini sokubonisa. Kulula ukuyisebenzisa futhi ingasebenza nge-busbar arc ewusizo ngokubukeka okuhle.

Inzuzo

Lo mshini usetshenziselwa ukwenza imishini ye-arc yesigaba samakhanda e-busbar ane-H≤3-15mm, w≤140mm kanye ne-L≥280mm.

Ikhanda lebha lizohlanganiswa ngomshini ukuze libe nesimo esiqinile.

Ama-clamp asebenzisa ubuchwepheshe bokubeka phakathi okuzenzakalelayo ukuze acindezele ikhanda lokucindezela kangcono endaweni yokuthwala amandla.

I-booster isetshenziswa ekhanda lokucindezela ukuze kuqinisekiswe ukuzinza kwento yokusebenza, okwenza kube nomphumela ongcono wokusebenza.

Isibambi samathuluzi se-BT40 esijwayelekile emhlabeni wonke sisetshenziselwa ukufaka esikhundleni se-blade kalula, ukuqina okuncane kanye nokunemba okuphezulu.

Lo mshini usebenzisa izikulufo zebhola ezinembe kakhulu kanye neziqondiso eziqondile. Kukhethwe izinsimbi zokuqondisa ezinkulu ezisindayo ukuze zinikeze ukuqina okungcono komshini wonke, zehlise ukudlidliza nomsindo, zithuthukise ikhwalithi yomsebenzi futhi ziqinisekise ukunemba nokusebenza kahle okuphezulu.

Isebenzisa izingxenye zemikhiqizo yasekhaya neyaziwa emhlabeni wonke, lo mshini uhlala isikhathi eside futhi ungaqinisekisa ikhwalithi ephezulu.

Uhlelo olusetshenziswa kulo mshini luyisofthiwe yokuhlela ihluzo ezenzakalelayo efakwe yinkampani yethu, eqaphela ukuzenzekela kohlelo. Umqhubi akudingeki aqonde amakhodi ahlukahlukene, futhi akudingeki azi ukuthi angayisebenzisa kanjani isikhungo somshini wendabuko. Umqhubi kufanele nje afake amapharamitha amaningana ngokubhekisela kumahluzo, futhi imishini izokhiqiza ngokuzenzakalelayo amakhodi omshini. Kuthatha isikhathi esifushane kunohlelo oluqhutshwa ngesandla futhi kususa amandla ephutha lekhodi elibangelwa uhlelo oluqhutshwa ngesandla.

I-Busbar efakwe kulo mshini ibukeka kahle, ayinawo ugesi ophumayo, inciphisa usayizi wekhabhinethi ukuze kongiwe isikhala futhi inciphise kakhulu ukusetshenziswa kwethusi.

Le nkampani isekela ifilosofi ethi “Yiba No.1 ngokuhle kakhulu, gxila esilinganisweni sesikweletu kanye nokwethembeka ukuze ukhule”, izoqhubeka nokusebenzela amakhasimende asebekhulile namasha avela ekhaya nakwamanye amazwe ngokushisa okuphelele kwe-MOQ Ephansi ye-CNC Copper High Effiency Automatic Busbar Bending Punching Cutting Machine, Senza konke okusemandleni ethu ukuhlinzeka ngosizo oluzuzisa kakhulu kubathengi abaningi nosomabhizinisi.

I-MOQ ephansi ye-Umshini Wokusika waseShayina Wemishini Yebhasi Nebhasi YokubhobozaNjengoba umgomo wokusebenza “ugxile emakethe, ukwethembeka njengomgomo, ukuzuza kowina njengomgomo”, sibambelele “kumakhasimende kuqala, isiqinisekiso sekhwalithi, isevisi kuqala” njengenhloso yethu, ezinikele ekuhlinzekeni ikhwalithi yokuqala, ukudala isevisi yobuhle, sithole udumo nokwethenjwa embonini yezingxenye zezimoto. Esikhathini esizayo, sizohlinzeka ngomkhiqizo osezingeni eliphezulu kanye nensizakalo enhle kakhulu njengokubuyisela kumakhasimende ethu, samukele noma yiziphi iziphakamiso kanye nempendulo evela emhlabeni wonke.

Ukucushwa

| Ubukhulu (mm) | Isisindo (kg) | Usayizi Wethebula Lokusebenza (mm) | Umthombo Womoya (i-Mpa) | Amandla Aphelele (kw) |

| 2500*2000 | 3300 | 350*900 | 0.5~0.9 | 11.5 |

Amapharamitha Obuchwepheshe

| Amandla kaMama (kw) | 7.5 | Amandla eServo (kw) | 2*1.3 | I-Max Torpue (Nm) | 62 |

| Imodeli Yesiphathi Sethuluzi | I-BT40 | Ububanzi Bethuluzi (mm) | 100 | Isivinini se-Spindle (RPM) | 1000 |

| Ububanzi Bezinto (mm) | 30~140 | Ubude Bezinto Ezincane (mm) | 110 | Ubukhulu Bezinto (mm) | 3~15 |

| I-X-Axis Stoke (mm) | 250 | I-Y-Axis Stoke (mm) | 350 | Isivinini Sesikhundla Esisheshayo (mm/min) | 1500 |

| Iphimbo le-Ballscrew (mm) | 10 | Ukunemba Kwesikhundla (mm) | 0.03 | Isivinini Sokudla (mm/min) | 1200 |